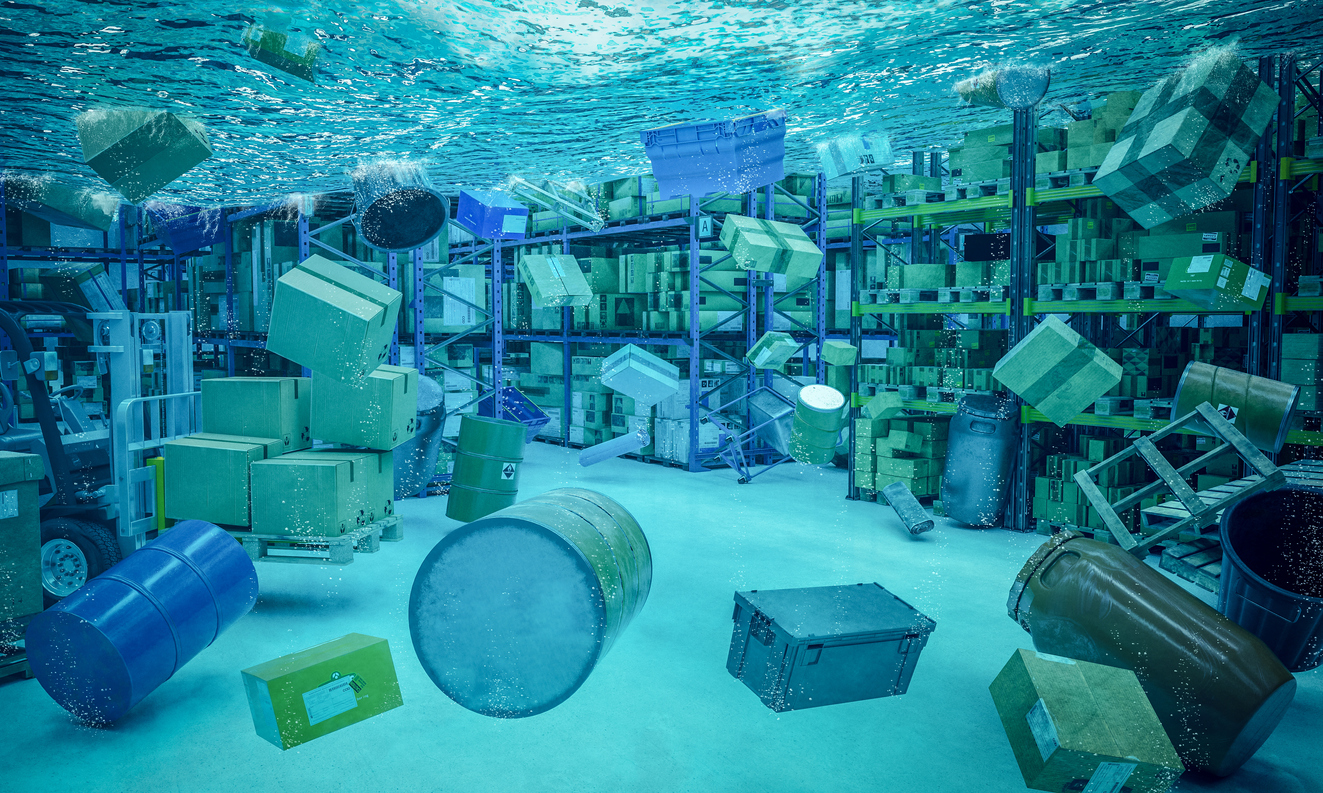

Implementing safety protocols in your business’s warehouse is essential to ensuring a healthy environment. Additionally, warehouses are typically bustling places, with the noise and activity contributing to a general frenzied atmosphere. Chaos and confusion can lead to an increased risk of accidents, some of which could result in severe injury and death. Thus, it is why getting commercial lines insurance is so crucial.

As warehouse owners, your clients are responsible for implementing safety protocols and ensuring that employees follow them. Also, it is imperative in distribution, where warehouses have plenty of hazards.

According to Occupational Safety and Health Administration (OSHA), this field has more fatalities than any other, making safety precautions essential.

Guidelines for Ensuring Warehouse Safety

OSHA recommends the following guidelines for ensuring worker safety in a warehouse environment:

● Ensure adequate ventilation in all areas

● Implement comprehensive lockout and tag-out procedures

● Install barriers in front of open and exposed loading doors

● Block off sites where there is a risk of falling more than four feet

● Remove obstructions and tripping hazards from aisles, floors, and joint surfaces

● Train employees on safe working practices in hot and cold environments

● Instruct employees on standard ergonomics for general and specific procedures

● Mandate regular rest breaks for employees that perform physical tasks

● Account for safe practices when determining task completion and project timelines

Common Safety Risks in Warehouses

Apart from the general guidelines listed above, warehouse managers and personnel should also keep the following in mind when working in specific areas or performing specific tasks:

Forklift Operation

Warehouse accidents are usually the result of improper operation of forklifts. Unfortunately, many of these incidents involve repeated OSHA violations.

Warehouse administrators can reduce forklift-related accidents by training and certifying forklift operators and establishing safe operating policies. It is also advisable to install impact-tested safety barriers to protect workers from heavy machinery.

Communications

All warehouses should have a comprehensive and clearly-defined communications protocol for accidents and other unforeseen incidents. When problems occur, warehouse personnel should be able to communicate with managers and supervisors quickly.

Electrical Work

Working with electrical systems is a common risk factor among warehouse employees. Adherence to OSHA standards for electric wiring is vital, including ensuring proper grounding and circuitry installation. These steps can help reduce electrical hazards and prevent fires.

Owners must install ground fault circuit interrupters as needed. There should also be a program for installing equipment grounding for all conductors.

Safety barriers such as Systems Protector should cover all electrical wiring. It prevents impact damage resulting from pallets, forklifts, and stock carts.

Respiratory Concerns

Warehouse owners are responsible for ensuring their employees’ well-being and respiratory health. Providing them with industry-standard respiratory equipment is vital, as it helps reduce the risk of inhaling harmful substances.

You must help employees understand the risks involved and how to maintain and care for the PPE assigned to them. These policies will hopefully minimize incidents resulting from the ingestion of potentially hazardous toxins.

Trips, Slips, and Falls

Falling objects can cause severe injuries and property damage. It is imperative to install precautionary mechanisms in and around designated fall zones. Safety barriers can reduce the risk of fall-related injuries considerably.

Fall restraint systems such as railings and guardrails are especially effective in warehouse environments. Your clients should also consider installing safety nets and other “fall arrest” systems around accident-prone areas.

Conclusion

Despite the many risks involved in working in a warehouse, it is possible to prevent accidents and reduce the risk of injury. Moreover, developing effective safety protocols is an essential first step. Additionally, ensuring that workers implement them properly is just as crucial. By getting everyone involved and cultivating a company-wide policy of safety and precaution, it may be possible to drastically reduce the number of unfortunate incidents.

About Snyder Specialty

Snyder Specialty, LLC is a New York-based underwriting facility that provides a range of property and liability solutions for personal and commercial lines. Specializing in coastal properties and hard-to-place risks, Snyder Specialty expands your current capabilities with proven solutions for complex risks. Find out more about the company’s range of services by calling (718) 362-8039.